8th December

Topic of this week is SALT! Salt of the earth and salt of the sea. I start off with a few facts about salt and health, followed by ways that ocean salinity is already changing. This brings me to Desal & other uses for waste brine, including food industry, road gritting and sodium ion batteries.

Part 1 – Background information, on the importance of balancing salt & water

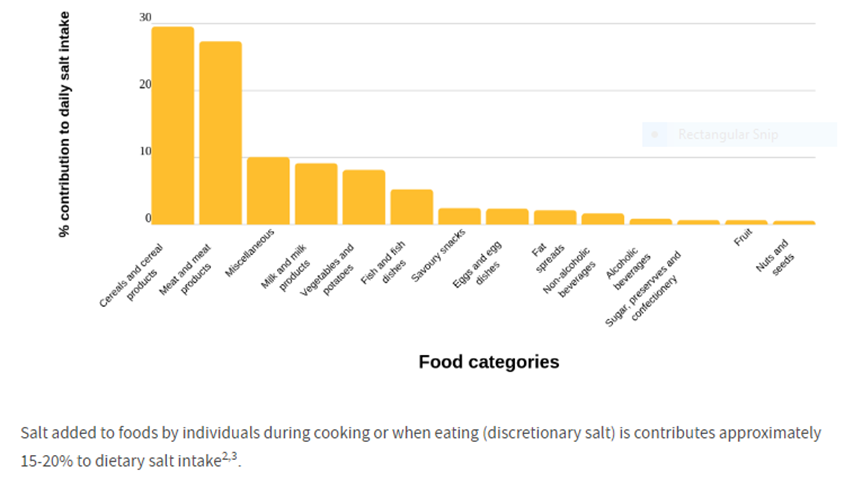

Sodium Chloride, or common salt, is an absolutely vital component of a well-functioning human body, but – with the likely exception of people experiencing high blood-pressure – we hardly ever give a thought to this. Although not relevant to sustainability, I wonder if the following chart may surprise readers? Cereals and meats, are the sky-high bars on this chart. I guess salted/preserved meats are fairly obvious, but I had no idea about cereals!

How do the 2 items, salt and water, co-exist in the body? “Well, WATER and SODIUM LEVELS are a double act whereby water acts to hold the sodium ion in the body, so we must look at the two together when it comes to achieving the correct balance.”

This is already fascinating stuff to me, but again not strictly relevant. If you want to pursue, try this link https://www.precisionhydration.com/performance-advice/hydration/sodium-fluid-balance/

OR useful for Chemical and Medical info is https://www.medicalnewstoday.com/articles/146677

Sodium makes up 40 percent of salt. If a food label lists sodium instead of salt, multiply the answer by 2.5 for an accurate picture of the salt content. Most Americans (and probably UK residents are very similar) take in too much salt, and 75 percent of it is hidden in processed and packaged food.

The American Heart Association (AHA) recommends a maximum intake of no more than 2,300 milligrams/ 2.3 grams or around 1 teaspoon intake per day, and preferably no more than 1,500 mg.

Balance of salt and water in our oceans

If many people lack understanding of salt and body fluids, even more of a mystery to most of us is the balancing act in our oceans. I was pleased to discover a really useful overview of the topic – albeit in an outdated 2009 report – that includes some great work by Peter Stott, a leading expert at Exeter Met Office:-

“Ocean Salinity levels are important for two reasons. First, along with temperature, they directly affect seawater density (salty water is denser than freshwater) and therefore the circulation of ocean currents from the tropics to the poles. These currents control how heat is carried within the oceans and ultimately regulate the world’s climate. Second, sea surface salinity is intimately linked to Earth’s overall water cycle and to how much freshwater leaves and enters the oceans through evaporation and precipitation. Measuring salinity is one way to probe the water cycle in greater detail.

In the last half-century or so, the sub-tropical Atlantic has been getting gradually saltier — a less than 1 percent increase in real terms, but an effect that is nevertheless significant. ‘It might sound like quite a small change,’ says Stott, ‘but the overall salinity of our oceans is naturally relatively steady, so it’s actually a lot of fresh water being factored out of the ocean.”

Stott’s work was picked up at that time and shared online by NASA, because they were developing a spacecraft for measuring sea salinity from orbit. It took about 2 years to get the craft launched and reporting back, then data was received until June 2015, when the project had to be aborted due to a power failure. You can read about the mission in either the short online NASA report

https://climate.nasa.gov/news/58/with-a-pinch-of-salt/ or the more general overview of Wikipedia https://en.wikipedia.org/wiki/Aquarius_(SAC-D_instrument)

What does Desalination do to ocean salinity?

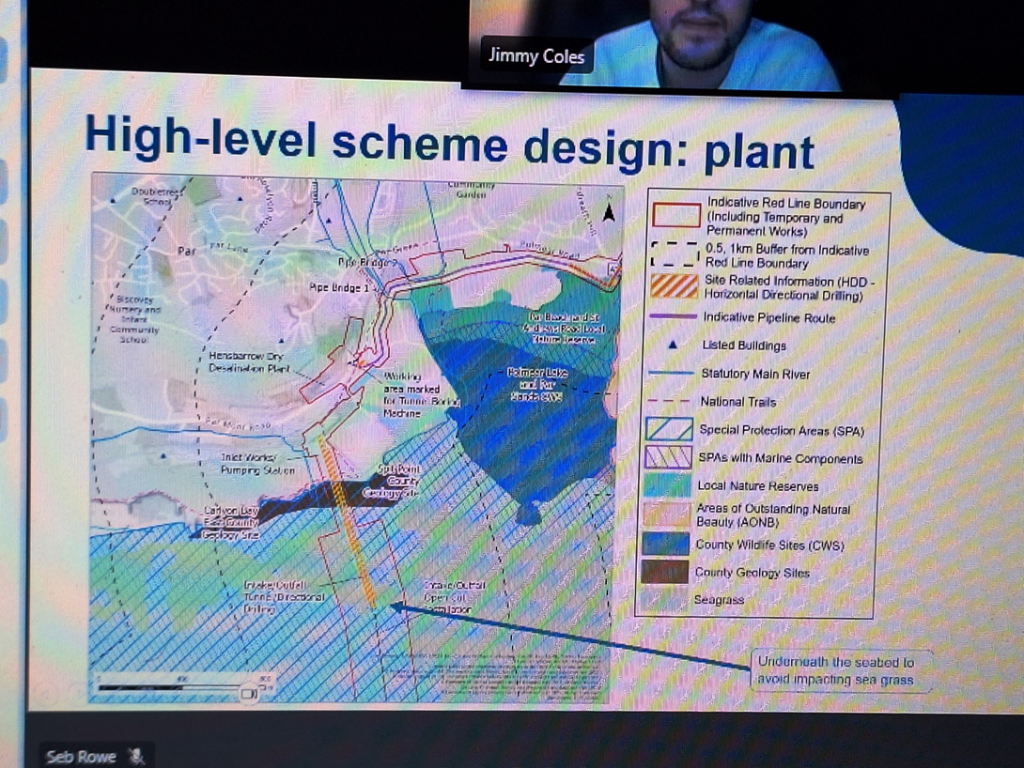

My understanding of this question was taken to a new level, when I participated in the first Teams Q & A run by Southwest Water on Monday 4th December. There was a lot of content, but today I really want to focus on a single element – will the waste brine have a bad effect on our seagrass and maerl, plus the commercial seaweed and mussel farm in Par Bay? The lead engineer, Michael Gardner told us that the plan is to drill beneath the seabed and emerge with an exit pipe from below the seagrass. I am not convinced that is a good idea, since I have the impression that the whole point of seagrass is to sequester carbon in its roots as well as the leaves.

https://www.nature.com/articles/s41598-021-90544-5

“It is estimated that seagrass globally stores 140 Mg organic carbon (Corg) per hectare in the top meter of soils, accumulated over centennial-millenial time scales, being up to 40 times more efficient at capturing organic carbon (Corg) than land forests soils”

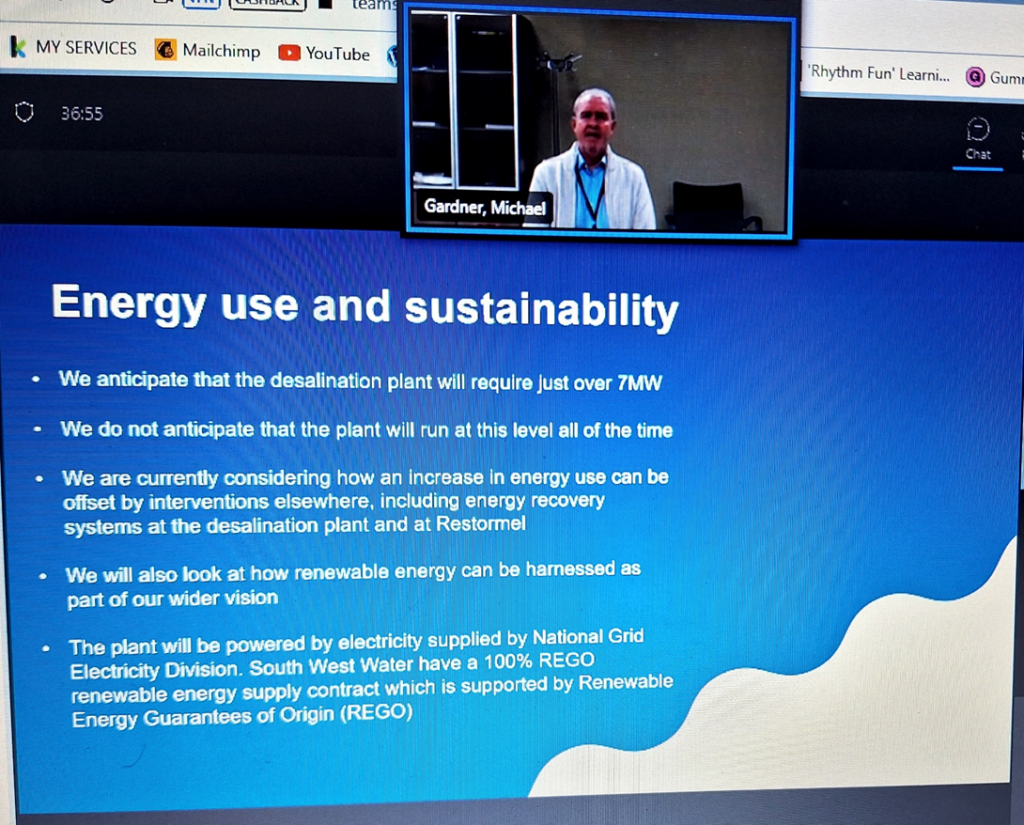

I include below the most important slide from the SW Water presentation, plus one more about energy use. I snapped many more, so please email or message to receive further, if you wish.

We were advised that the company can assure us “the concentration of salinity will be dispersed within a 78m distance from the outfall pipe”. I cannot accept that either. What proof is there? I shall be facing them with all of this at the public open event, on Monday next, 11th December in Alexandra Hall, St. Blazey. There is a 2nd event in Lostwithiel Church Rooms on Tuesday 12th.

Part 2 – What else is waste brine good for? Can we create a circular economy? Background info …

History of Salt in Food

Through the centuries salt has played a very vital role in preserving food, long before we had refrigerators to help. And, happily, the addition of salt could render unhealthy food more palatable too. Here is a useful history, from https://www.madgetech.com/posts/blogs/7-ancient-methods-of-food-preservation/#:~:text=As%20a%20form%20of%20dehydration,that%20need%20moisture%20to%20survive.

Since the beginning of time, humans had to get creative when it came to survival. Ancient cultures around the world had to harness nature for local food sources while acclimating to the climate. Whether hunting or harvesting, food preservation allowed man to plan ahead and form a food supply. This was not only crucial for survival, but also for putting down roots and establishing communities.

As ancient cultures were adapting, they discovered techniques that have now become basic methods of food preservation.

- DryingThe earliest form of curing meat was dehydration using the sun or wind. Dehydration dates back to the Middle East and oriental cultures that dried foods in the hot sun as early as 12,000 B.C. In regions without enough sunlight or wind, “still houses” were built and heated using fire to dry fruits, vegetables, and herbs.

- CuringAs a form of dehydration, early cultures used salt to help dry out foods. The curing of meats and seafood not only preserves the taste and texture but also prevents the growth of harmful pathogens that need moisture to survive.

- FreezingIn climates that experience freezing temperatures, freezing was an obvious method of preservation. Food was buried underground or in the snow for preservation throughout the winter. This method led to the construction of “icehouses” or “iceboxes” for storage until the 1800’s when artificial refrigeration was invented.

- FermentingA valuable method of preservation, fermentation prevents food from spoiling by using microorganisms to destroy harmful pathogens. The production of acid or alcohol during fermentation creates vitamins making fermented foods more nutritious and flavorful.

- PicklingA form of fermentation, pickling preserves foods in vinegar produced by starches or sugars. Pickling may have originated when food was placed in soured wine or beer to preserve it. It’s believed Indians were the first people in Asia to make cucumber pickles more than 3,000 years ago.

- Sugaring

Known to the earliest cultures, sugaring preserves food in honey or sugar. The sugar not only sweetens but draws out water from harmful pathogens, which dehydrates and destroys them. The ancient Greeks and Romans mastered the technique of using heated sugar and fruit pectin which we have come to know as jams, jellies, and preserves. - Canning

Dating back to the 1790s, canning is the newest method of food preservation which involves the heating and cooling of food in jars or cans. Heating destroys harmful pathogens, while cooling creates a vacuum seal to prevent contamination and deterioration.

Sources and types – today the UK produces 3m tons of salt per year! Who knew?

https://saltassociation.co.uk/education/salt-history/

About 4,700 years ago, the Chinese Png-tzao-kan-mu, one of the earliest known writings, recorded more than 40 types of salt. It described two methods of extracting and processing salt, similar to methods still in use today:-

Rock Salt Mining

Rock Salt Mining happens underground with the salt being physically dug out of the ground. Enormous machines work in a network of gigantic caverns and tunnels, drilling, blasting and crushing rock.

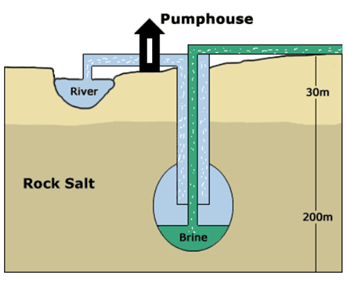

Brine Evaporation linked to Solution Mining

In solution mining, salt is extracted by forcing water under pressure into a borehole, drilled into an underground salt bed or dome. The salt dissolves, turning the water into brine and creating a cavern in the salt-bed.

The brine is then pumped back to the surface and on to the purification plant where calcium, magnesium and other impurities are removed before beginning the brine evaporation process. This involves a long sequence of processes, through a vacuum plant made up of closed cylindrical vessels, or ‘effects’, containing steam chambers, which in turn contain a series of tubes.

Brine Evaporation of Sea Salt

In hot countries, salt is also produced by allowing the sun to evaporate seawater in shallow pools (or ‘pans’) in a method called Solar Salt Production. Regrettably, because of our low average temperatures and high rainfall, there’s no solar salt production in the UK.

Cornish Sea Salt confirms that sadly, even in West Cornwall there is no solar drying of salt. On a day like today, I can certainly see why! However, they do not use the vacuum system described above, rather a slightly modified Iron Age method of filtration and heating in big vats. More on this below.

UK Rock Salt Mining for roads

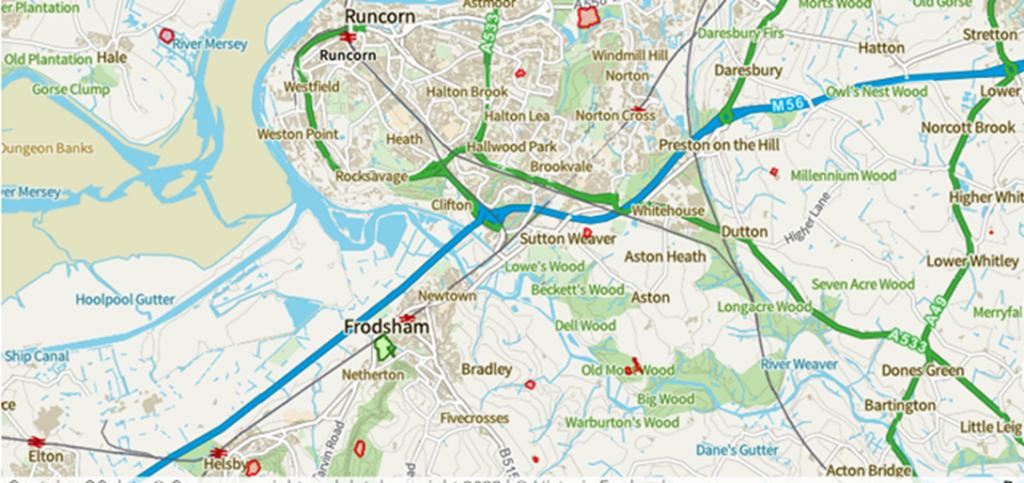

Our centres for this are in County Antrim, NI and in Cheshire. In both cases the main product is for gritting our icy roads – a good topic for December! As it happens, probably to your surprise, I can talk with some personal knowledge about the salt mines of Cheshire.

As a very young child, with my mum and sisters, I quite regularly visited an area of Cheshire beside the River Weaver, and learned where salt was mined. There was no road to my uncle’s house, so we all had to use either a little motor launch or a rowing boat. I remember taking the rowing one out and being terrified out of my wits, when a huge dredger came along and almost crushed me into the banks!

A cousin has kindly supplied a couple of photos from back then to accompany this history of salt mining in that area.

Within that report is another link to a selection of recorded interviews. The first is about the salt boats on the Weaver, from c 1949, to the heyday of Rock mines in the 1960s. Initially they made lumps of rock salt for use as licks for animals or crushed as fertiliser, for farms all around the world; this salt was moved in the boats. From the start of the 60s a change was seen, replacing boats with aluminium-lined road tankers, on the way to meet growing demand for salting of new motorways. A million tons per year from one ‘shaft’ was reached quite soon, increasing when compressed air drills were replaced by electric powered. http://www.weaverparkway.org.uk/listen.php?f=2

The speaker describes various types of salt for human consumption including Dendritic, which was the preferred salt for African markets, as it had different qualities ref holding moisture. It was made of brine boiled at a lower temperature in the vacuum = a special process. https://www.makeitnatural.co.uk/products/dendritic-salts-1 A 2nd special recipe turned the salt into small ‘ball bearings’, in a dedicated mill in Staffordshire.

Another story was of a young lad on his grandfather’s boat, blowing the whistle to alert folks at the Northwich swing bridge from where it took one day to Acton Bridge, passing my uncle’s house, Pickering’s Bridge Cottage on the way.

CONCLUSION re BRINE USE OPTION 1 – I cannot see any reason why we shouldn’t add Par Bay brine waste to Cornwall’s supplies for winter gritting of roads? But what about using it in food?

Cornish Sea Salt

The original founder, Tony Fraser, came across an Iron Age salt works in a remote cove on the south coast of Cornwall while out walking. Most people would have made a mental note and carried on with their lives, but Tony wanted answers: why had such an essential element of the county’s farming and pilchard industry died out? Because rock salt had become an easier way of harvesting the mineral.

The idea affected him so profoundly that he was determined to re-imagine the sea salt industry for the 21st century, so he set out to bridge the ancient and modern worlds. Production is still inspired by the original methods of harvesting the goodness of the ocean. Referencing centuries old techniques, took us on a journey around the world to source electrolytes from natural sea salts to enrich our brines, allowing the correct conditions for our sea salt flakes to form.

The production process is simple: we use 15,000 tonnes of fresh seawater each day, and from this, only half a percent of salt is harvested and the rest is returned to the sea. Our impact on the environment is zero. We have developed low impact, pioneering technology to filter the seawater and remove impurities. The resulting blend of sea minerals create a saturated brine then moves to crystallisation rooms where, based on traditional Iron Age methods, it is poured into huge vats and gently heated.

The addition of heat onto the concentrated brine is when the magic happens. Salt crystals begin to form on the surface of the water and either drop to the bottom as crystal shapes for our crunchy Cornish Sea Salt Original or, in shallower tanks, the salt forms pyramids on the surface to create our more delicate Cornish Sea Salt Flakes.

It takes an expert team to gauge the right moment to hand harvest, dry and package the salt crystals on a journey which begins in Cornish waters and ends in the kitchens of cooks, chefs and food lovers from all over the world. Significantly less sodium, with a unique combination of minerals and great tastes! https://www.cornishseasalt.co.uk/pages/made-by-the-sea

CONCLUSION re BRINE USE OPTION 2, food industry

SW Water has make an approach to the Cornwall Sea Salt company, I quote – “Philip spoke with the design engineers working with SWW on the potential brine coming from the desalination process, but it hasn’t gone any further at this time. It sounds like they are talking about masses of fairly low-grade brine, which wouldn’t be a lot of use to us.”

Lower grade quality salt could still be used in food processing, but this needs further research.

BRINE USE OPTION 3 – Sodium Ion batteries

This blog is already quite a long one, so I will postpone a conclusion til another day, in 2024. But a summary is to be found at

https://www.gep.com/blog/strategy/lithium-ion-vs-sodium-ion-battery

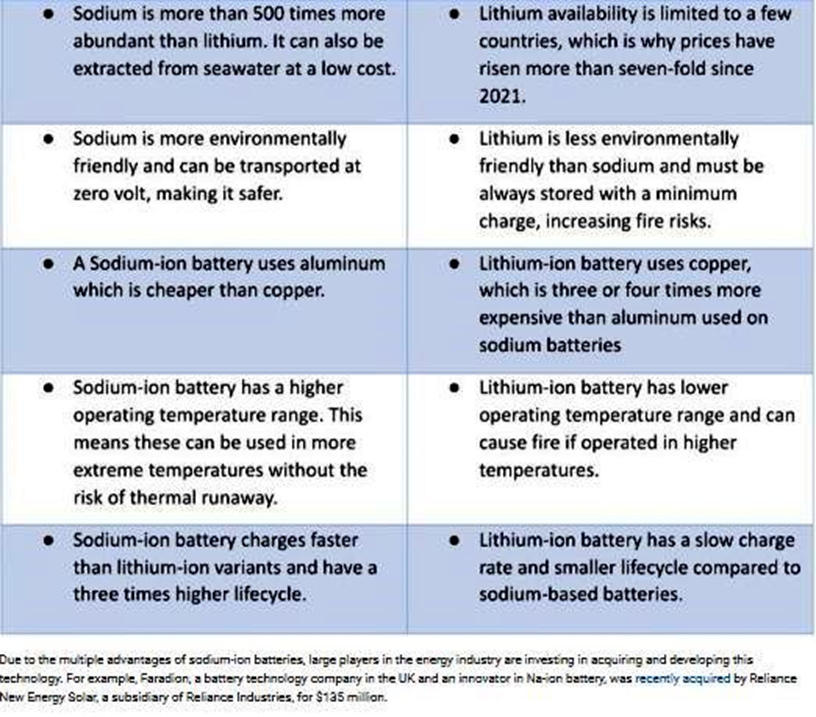

Sodium-ion batteries are a promising alternative to lithium-ion, which are currently the most widely used type of rechargeable battery. Both types of batteries use a liquid electrolyte to store and transfer electrical energy, but differ in the type of ions they use.

An examination of Lithium-ion (Li-ion) and sodium-ion (Na-ion) battery components reveals that the nature of the cathode material is the main difference between the two batteries. Because the preparation cost of the cathode from raw materials is the same for both types of battery technologies, the main cost reduction for sodium-ion batteries comes from raw materials.

Price is not the only positive aspect for Sodium ion. Availability and reduced environmental impact compared with Lithium mining is a major consideration. You will see the vital sentence in the table below – ‘it can also be extracted from seawater at a low cost’.

However it is early days for this technology – “While there are many potential advantages to using sodium-ion batteries over lithium-ion batteries, there are also several challenges that need to be overcome before they can be widely adopted as a replacement.

If sodium-ion batteries are to become the backbone of the energy storage industry, they must continue to improve their technical performance. Researchers are working to improve the performance and stability of the batteries, as well as to reduce their cost, while companies are looking to establish a supply chain for the materials used in the batteries.”

I am sure you can tell, I have found this topic unusually fascinating! Sorry if it has gone on too long for you.

I will end now by advising that next time I hope to have further input on brine from Genesis, a report on the public meeting with SW Water, followed by results from COP 28 and a few photos and report of Cornwall Sustainability Awards. It will be the final blog before Christmas and please look out for it on a different day, TUESDAY 19th DECEMBER.

2 thoughts on “GF Blog 23 – Week 45”

Very interesting information. Let’s hope SWW take notice.

Thank you Auriol Tucker! This topic has got me hooked, with so many complex, interlocking strands to consider. But the basic is we must not them drill and insert a great big pipe beneath the seagrass and maerl and most certainly should oppose the release of toxic brine. In Week 31 I mention a contact at the United Nations. Maybe that is someone i should contact next!