17th FEBRUARY

Introducing the ABC of climate education; a little survey of print & paper & a very deep dig by the BBC’s ‘Underground Britain’.

The first draft of a running order for the upcoming ‘Ceremony of Climate Hope’ has been drawn up and we now know that the Bishop of Truro will be joining us – an honour, albeit a really unexpected one!

There is much that could still change, but the core message of ‘ABC’ is finalised. A stands for ADAPT, B for BALANCE and C for … numerous options re communication, but the best is probably CONNECT.

This week let me share some info about an ADAPT story. With Red Moor school I will be looking at the wonderful Baobab trees of Africa, the plant equivalent of a camel! They take in a lot of water when it does rain, then store it and eventually produce uniquely nutritious fruits. This was a totally new discovery for me, which has been possible through talking with the folks in the UK who make and sell Baobab fruit powders and other products. It really does sound like a miracle tree, hence I thought you might like to know about it too. https://aduna.com/blogs/learn/the-baobab-tree

Content borrowed from Aduna website – The majestic baobab tree is an icon of the African continent and lies at the heart of many traditional African remedies and folklore. Native to the African savannah where the climate is extremely dry and arid, it is a symbol of life and positivity in a landscape where little else can thrive.

Over time, the Baobab has adapted to its environment. It is a succulent, which means that during the rainy season it absorbs and stores water in its vast trunk, enabling it to produce a nutrient-dense fruit in the dry season, when all around is dry and arid. This is how it became known as “The Tree of Life”.

The bark can be turned into rope and clothing, the seeds can be used to make cosmetic oils, the leaves are edible, the trunks can store water and the fruit is extraordinarily rich in nutrients and antioxidants. Women in Africa have turned to the baobab fruit as a natural source of health and beauty for centuries.

The baobab is a prehistoric species which predates both mankind and the splitting of the continents over 200 million years ago. It grows in 32 African countries and one tree can live for up to 5,000 years, reach up to 30 metres high and up to an enormous 50 metres in circumference. Baobab trees can provide shelter, food and water for animals and humans, which is why many savannah communities have made their homes near them.

Going greener in print

It is the nature of a learning centre that we need quite a bit of printing. Around the outdoor areas, to be longer lasting than paper (that has to be plastic coated or encapsulated) increasingly we are using other types of materials. This very morning I spent a few hours painting enormous signs onto huge sheets of metal, acting as an assistant to our wonderful artist, Louise. We intend to use new materials for boards and banners, as well. But still, we will need some print on paper so I was pleased to receive a little guide ‘Print and Paper, myths and facts’ from St Austell Print Company. SAPC have teamed up with an organisation called www.twosides.info, who want us to print on both sides of paper as much as possible. Together their message is clear – this is an industry very switched on about sustainability, not only publishing the facts but also challenging greenwashing.

Some of what I learned:-

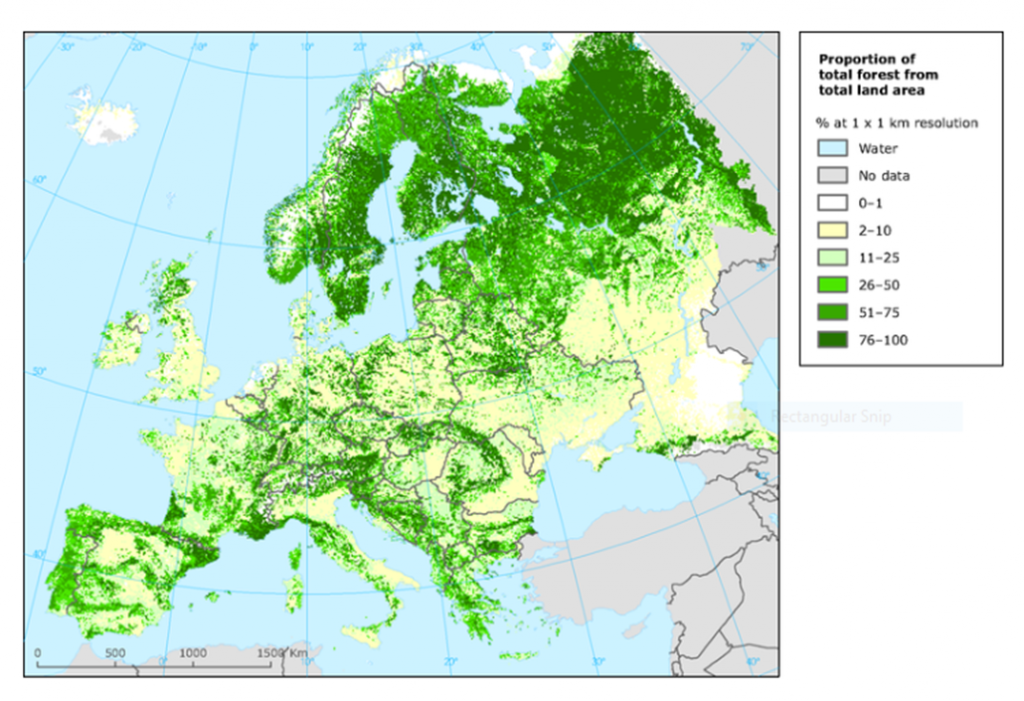

- Approximately 40% of Europe’s land mass is covered by forests.

- The quantity of these European forests is growing by over 1,500 football pitches every day. This translates into approximately a 2% increase per year, but bear in mind it is managed forests, grown to be cut and used within about 40 years.

- Half of the world’s wood harvest is used for fuel; about 30% is for other industries; less than 15% is taken for making paper. Having said that, however, one must take care over quoting percents – listen to this at 22 minutes in, a survey into the number of trees being cut down to make loo rolls! Radio 4’s More Or Less

- Although paper is highly recycled, virgin fibres have to be mixed in to maintain the required quality for our paper industry. Currently the mix is about 56% recycled and 44% new.

- Between 1990 and 2019 carbon emissions of the sector reduced by 48% per tonne so that today most of the energy used for paper manufacture is described as renewable. BUT, looking closer, I am worried that more than half is from burning biomass, is that a good choice? Are paper mills making their own waste wood into fuel? They say they are. The materials shown below – sawdust, bark and ‘black liquor’ (a derivative from the pulping process) – are called ‘Residuals’ and, as described in this video, are being used for Combined Heat and Power energy efficiency. https://www.twosides.info/UK/biomass-carbon-neutrality/

- It is often claimed that paper making consumes excessive quantities of water, which is why the mills are frequently found beside rivers or lakes. But the word ‘consume’ is misleading. Water may be circulated several times, after which it will be subject to filtration, sedimentation, flotation and other biological treatments, enabling almost all of it to return safely into the water courses.

- Another common message tells us that electronic communications are much more responsible environmentally. But we cannot ignore the use of electricity by ICT; it consumes between 5 and 9% of all EU electricity, which is equal to the carbon footprint of all air traffic! It is predicted, if left unchecked, it could reach 14% of all global emissions by 2040.

- A further consideration of ICT is the growing mound of electronic waste. In 2019 we made 53.6 million tons of it across the world, and less than 18% was able to be recycled. This is very bad news, when we should be making huge efforts to save and re-use the finite precious metals involved. ☹ This brings me to my 2nd topic of the week …

Underground Britain

Although not an ardent follower, I do sometimes enjoy dipping into Countryfile on a Sunday evening. The broadcast on Feb 5th ticked every box imaginable, for me!

https://www.bbc.co.uk/iplayer/episode/m001hz7x/countryfile-underground-britain

Most of the programme was shot in Cornwall, but with an acknowledgment that there are around 2000 working mines and quarries across the country and thousands more, currently closed down but with potential to help fulfill our future energy needs. Looking back to the 18th and 19th centuries, up to 10,000 tons of tin was being mined in Cornwall per year plus around 2/3rd of the world’s supply of copper. The Coal Authority responsibility for remediating mine waste is something I have read of and written about in the blog before. But seeing drone footage over Carnon River processing centre and learning greater detail of the what happens there was a real eye-opener!

The bright orange water tells us that iron has oxidized into a rust, but along with it comes also very high levels of cadmium, copper, zinc, arsenic and aluminium. The PH levels are highly acidic as well (3.5 against the desirable 7+). By the end of a process, which uses lime to treat a staggering 450L per second, the outcome is a residue of sludge plus safe and clean water going back to the river, at a level of PH9. BUT there are 2 things we hear little about. First is what happens to the sludge? The government website says

it is pumped to the Clemows Valley tailings dam, a 114 acre raised mine waste containment site, where it settles, dries and solidifies.

But is that a safe ending? Doesn’t heavy rain wash it back into the ground?

The 2nd thing we did not hear about was the cost! The plant has been operating for decades now, so any figures online could be outdated. It was not an immediately productive search but eventually I did track down the following, with ref to HDS or High Density Sludge treatment plants of this kind.

The cost of commissioning and operating such fixed structure HDS plants is extremely high. The Wheal Jane water treatment plant, Cornwall, which has a 1656 m 3 /h processing capacity, had a design build and 10 year operating cost of £16.9M with an operating cost of £1M/year and a capital cost of around £10M [6]. …

This site is just one of 200 being monitored by the EA across Cornwall .. a big challenge!

As you might expect, the programme looks into Lithium mining too. Both British Lithium, with their expertise in finding and processing lithium carbonate, and Cornish Lithium (which extracts from hot brine water in geo-thermal drilled boreholes) are reported on. Within about 3 years 20,000 tons of lithium could be brought out by British Lithium annually, sufficient for EV batteries of 300 – 400,000 vehicles. Cornish Lithium, with its extraction from water, still appears to be in its infancy. I wish there would be more/better analysis of places on the other side of the world where Lithium mining has already caused devastation, like Chile for example. Personally, I am very concerned about these plans and don’t even accept that EVs are the right way forward, in the long run …

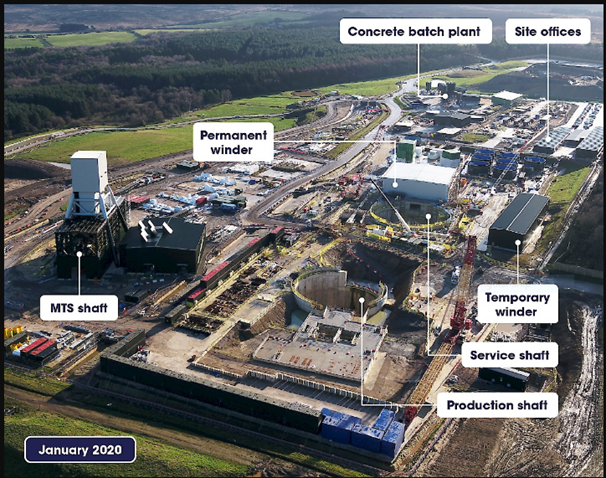

New info for me and very interesting was a section about a unique type of mining under the North Sea.

The quarry is over 1 mile down and 5 miles out, extracting a kind of rock-fertiliser for farmland, (its called poly sulphate or polyhalite). They then must run it back to the main shaft, via a road that looks the size of motorway and is 42 degrees Centigrade heat to work in.

Miners all over the world will be familiar with such hot, dark tunnels!

What I loved best about this story was the field trials, where cows all chose to go over to the sulphur-enriched side of one field to graze and this reinforced to the farmer that he had a severe lack of sulphur in the soil.

Unfortunately, in the heart of the North York Moors national park, the Woodsmith mine site is not a pretty sight! And that makes for a realistic conclusion – mining and quarrying will rarely be a win win solution. It always causes some damage to the environment, so far as I can tell. We have to be ultra-careful embarking on such ventures.

Between all the technical stuff about mining is a welcome gentle section of programme (about 25 minutes in), with an ecologist and bat expert, entering 2 old mines that are just on the opposite hillside very close to Meadow Barns. After a break without monitoring, due to Covid, Sam Smith is a very happy bunny, finding evidence of many bats roosting in the old tunnels in the Prideaux Woods, including some of the rare greater horse-shoe species.

Conclusions

The ABC of climate has to be borne in mind for Cornwall’s mining future too. Yes, we can and should Adapt our old infrastructure, but – as you will hear from us in future – there can be less expensive options, small & local scale, causing far less environmental damage. If we apply thoughts about Balance, is the size & significance of outcome from lithium mining a justification for current plans? And Connect … we should try to communicate with people in Chile, to hear their advice on lithium mining!

FINALLY the reminder

of what appears to be a very interesting event in March, which I mentioined last time. I have booked to be there on Thursday 2nd but there is another option on 1st. I will let you know what I learn and – as you would expect – will drill down into the detail, challenge all claims and generally find if it is Green Washing or not.

2 thoughts on “GF Blog 23 – Week 3”

https://www.my-gambia.com/mymagazine/recipe-nan-mburu/

Easter treat using Baobab fruit.

I loved this film, Lin, thank you. The result isn’t a bread, or a cake is it? Seems more like a sweetened, luxury kind of porridge.

Did you make it or eat it on your travels?? Caroline x